- Article

gives origins of and steps taken to make Dhokra Art, why demand is falling and

what can we do.

India's cultural diversity comes to light in its various cultures. The country’s folk dances and handicrafts have successfully preserved its ancient art forms. One such art form is Dhokra Art (or Dokra Art). Before we dive into its making process, it will be worthwhile to know the history and origin of this fabulous ancient metal craft.

![]()

What is Dhokra Art?

The

art is a non-ferrous metal casting technique known as lost-wax casting or cire

perdue (in French). This technique has been known to be in existence for nearly

4000 years. A statue of a dancing doll excavated in Mohenjo-Daro is the oldest

known lost-wax technique artifact.

Where is Dhokra Art from?

The name ‘Dhokra’ is derived from the Dhokra Damar tribes of West Bengal who originally practised this art form. The metal casting artwork later spread its wings to the Central, Eastern and South India.

There

are two types of casting, Hollow Casting and Solid

Casting. The hollow casting is practised in Central and Eastern parts

which include Chhattisgarh, Madhya Pradesh, Jharkhand and West Bengal, while

the solid casting is practised in South India region including Telangana, which

was awarded GI tag (A geographical indication is a name or sign used on

products which corresponds to a specific geographical location or origin) for Adilabad Dhokra craft.

Dhokra

Crafts are created using Bell Metal which is an alloy of

Brass, Nickel and Zinc oxide. Even though the artifacts have their humble

beginnings in the clay core, they have, over the last few decades, gained

immense popularity globally.

Let

us explore the thirteen steps involved in the creation of Dhokra

Art.

1. Creating the Mould

Step

1 - The first step in the creation of Dhokra metal art is the powdering

and sieving of Black mud, or Kaali mitti, which is later on used for creating

the core clay model. This process is usually performed by the female section of

the household.

Step

2 - A coarse clay mixture is created as it is mixed and kneaded with rice

husk.

Step

3 - Once the soil dough is ready it is moulded into a model which is kept

in the sun and dried out completely. This step is crucial to ensure that the composite

mould model is devoid of any excess water and can retain its shape throughout

the process. The model can also be dried by gently firing in the oven. This

clay-mud model is in shape of the final cast.

2. Preparing Beeswax Strands

Step

4 - A Beeswax or resin bundle is used for the next step in the process.

With the assistance of an ingenious tool called Thassa, thin strands are extracted from beeswax bundles through a sieve-like tool called ‘Pichki’. The artist draws threads (as thin as 1mm in diameter) out of the wax bundle which will be then used to wrap up the clay model. This is the most crucial step in the creation of Dhokra art as it requires continuous practice to perfect the art of drawing the beeswax into thin wires and wrapping them around the mould deftly.

3. Covering the Mould

Step

5 - The artist then creates a sticky solution of green beans leaves

colloquially known as sem and the mould is covered with it.

Step

6 - The strands created in step 4 are used to cover the mould completely.

Step 7 - Additional designs, patterns and ornaments are separately made using the wax bundle and then attached to the mould. The final design can be seen as taking shape in this stage. Tools like wooden spatula are used to smoothen out any rough surfaces of the mould.

4. Preparing the Outer Covering

Step

8 - In the next step, a mixture of clay, sawdust, and charcoal is created,

and the mould is covered with it. The ducts are set up for wax to drain out and

melted metal to take over the cavity left by the wax.

Step

9 - The mould is dried out in the sun once again and another layer of clay

is applied. When this layer is dry a final covering of rice husk and dengur is

given to the mould.

5. Baking the Mould

Step

10 - The mould is now ready for baking. The artist bakes the mould at high

temperatures rising up to nearly 1100 degrees Celsius. This process melts away

the wax leaving a fine cavity between the two layers of the clay mixtures.

To see pictures

of moulding

6. Pouring the Metal

Step

11 - Pieces of brass metal are melted and this molten metal is poured into

the cavity through the ducts. As the melted metal hardens, it takes over and

adorns the shape and design of the mould.

Step

12 - The mould is then left to cool down for at least two to three hours.

Regular

spraying of water helps hasten the cooling process. It also makes the mould softer

and easier to break open.

The Superb Final Product is now Ready!

Step

13 - The mould is broken with a hammer and the final product is ready to

add a finishing touch to. The artist uses various tools to brush, file and buff

the finished product enhancing its beauty.

It

is important to note that the Bell Metal art technique requires expertise and

talent to make sure that all the 13 steps are carried out skilfully. The artist

has to ensure that the mould retains its shape until the final step of the

process.

As

detailed above, the process is extremely elaborate and time-consuming. It requires

years and years of practice to master. Further, each mould can be used only

once, therefore, each finished product is different and unique. The final

artifact can be created perfectly only when the artist has mastered the skill

of working with clay as well as metal. This metallurgical form of creating art

is not just one of the oldest but is also considered as the most advanced in

its field. No wonder we are all still mesmerized by the quaint beauty of these

handicrafts.

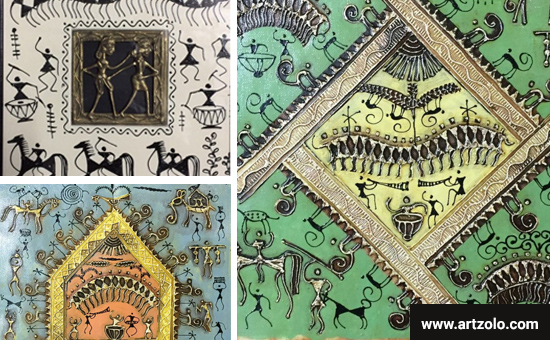

Motifs Utilised

Dhokra

is an ancient art and the motifs continue to have a primitive simplicity to

them. Thus, commonly occurring motifs

are religious images, Dhokra horses, elephants, peacocks, owls, measuring

bowls, and lamp caskets, etc.

However, the ‘primitiveness’ of these motifs do not show a lack of growth or that that they are anarchic. Rather they might hide profound wisdom. Even someone like Carl Gustav Jung, one of the biggest psychologists reads much in these archetypical symbols that keep recurring in the simple motifs of Dhokra arts.

Moreover, some of these symbols have something quite modern to them. Of

particular notice is an ancient artifact of a Dancing girl, who has that flirtatious smile on her face as she stands with her hand on her hip.

A Declining art

Dhokra art much like several other traditional arts is seeing a very fast decline. Unlike some of the other handicrafts that are declining in India, the problem with the Dokhra art is not a lack of demand. The demand is on the higher side – both domestically and internationally.

Rather

the problems are that first, the raw material is getting expensive. The

artisans are not always able to keep up with the increases in prices.

Secondly,

there are problems of logistics. The producers being small are unable to bring

their product to their consumers who are distant and often wide apart.

Thirdly,

with increased prices and logistics costs, the final artifacts themselves get a

bit too expensive and industrial products can often be cheaper.

Fourthly,

the industry remains untouched by any changes in technology. The artisans have

failed to use any mechanization to ease their load. There is a sort of

roughness to final products, a lack of final touch.

Fifthly, the newer generation is not showing much interest in art whose future seems a bit uncertain.

What can we do?

We

believe Dhokra art can be much helped by some marketing. The government could

use Dhokra artefacts to decorate government buildings. A government or

non-government agency might be created that will act as an intermediary between

artists and their customers. Some protection needs to be given to industry. And

research needs to be made in ways of improving the Dhokra technique.

Also

read about Dhokra Art

in Chattisgarh

Conclusion

Dhokra

art is an example of the ancient genius that has survived to this day despite

remaining unaffected by industrialization. It shows that art finds a way of

communicating itself whether or not there are technologies that support it. And

we hope it shall have a proposer as travellers are growing more and more

conscious of its importance.

References

and Also read

1. Lost wax casting

in India

2. The

Marvel of Adivasi Art

3. Bastar

Craft and Culture

4. Pictures of

Bastar Craft – shows making process of cast iron images.

To read all

articles by author

Cast Iron image, home of master craftsmen Dr Jaidev Baghel, Bastar. Pic 2013.

Cast Iron image, home of master craftsmen Dr Jaidev Baghel, Bastar. Pic 2013.

A wrought iron image in Tiku Ram home, Bastar. Pic 2013.

A wrought iron image in Tiku Ram home, Bastar. Pic 2013.

Work place of Dr Jaidev Baghel (expert in cast iron images) Kondagaon, Bastar.

Work place of Dr Jaidev Baghel (expert in cast iron images) Kondagaon, Bastar.

Detailed caption - Mould before

going into oven. Metal also melted in oven. Next metal poured on mould. When it

gets cold remove mud from image. U see two images kept for drying before it is

sent to the oven. When the two are joined final product is ready. Album

shows Lost Wax process called Cire Perdue in the West.

Last three pics by Sanjeev Nayyar.

The

purpose of this compilation is to document and promote. We have given credits

and reference links in this compilation. In case some are missed, it is not

with malafide intent.