- Article tells about the origin of Minakari art, what is the process, approach and application and where it is found in India.

The art of Minakari or Enamelling is called miniature of fire as well as the decoration of metal and tile with mina glaze. Minakari or Enamelling is the art of painting, colouring and ornamenting the surface of metals by fusing over it brilliant colours. These are decorated in an intricate design.

Mina is the feminine form of the Persian

word Minoo meaning heaven. Mina refers to the azure colour of heaven. The

Iranian craftsmen of the Sassanid era invented this art and the Mongols brought

it to India.

French tourist, Jean Chardin who toured

Iran during Safavid rule referred to an enamel work of Isfahan, which comprised

a pattern of birds and animals on a floral background in light blue, green,

yellow and red.

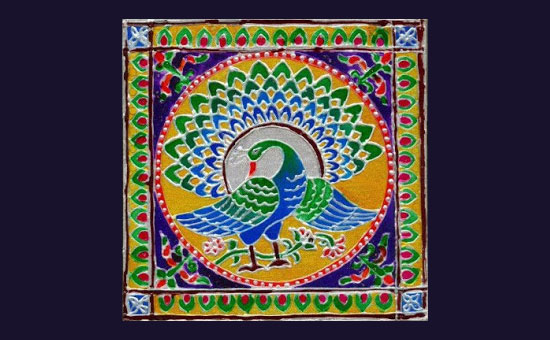

Minakari work.

Minakari work.

Enamelling is the art of colouring or decorating a metal surface by attaching or fusing pieces of different mineral substances over it. Enamelling is considered the most alluring and technical of all metal decorations. In the past enamelling was only done on gold, but presently it is done on other metals like silver, copper etc.

The art of decorating metal with Enamelling

or Meenakari was alien to India and was introduced by the Mughals. Raja Man

Singh of Amber (Jaipur) brought Meenakari to Rajasthan at the turn of the 16th

century. Man Singh brought skilful Minakars from the Mughal palace at Lahore

and established them in Jaipur, which became the centre of Meenakari.

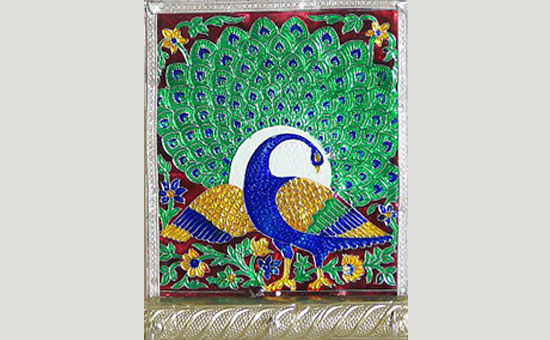

Meenakari art.

Meenakari art.

Process

The technique of Meenakari requires a

high degree of skill and application. The piece of metal on which Meenakari is

to be done is fixed on a lac stick. Delicate designs of flowers, birds, fish

etc are etched or engraved on it. This leads to the creation of walls or

grooves, to hold colour. Enamel dust of required colour is then poured into the

grooves and each colour is fired individually. The heat of the furnace melts

the colour and the coloured liquid gets spread equally into the groove. This

process is repeated with each colour.

As each colour is individually fired, colours,

which are most heat resistant, are applied first, as they are re-fired with

each additional colour. As a rule, white is the first colour applied and red

the last.

After the last colour has been fired,

the object is cooled and burnished or polished with agate. The depth of the

grooves filled with different colours determines the play of light.

Both silver and gold can be used as a

base for Meenakari. A limited number of colours, like gold, blue, green and

yellow, stick to silver, whereas all available colours can be applied to gold,

making it the preferred medium of enamellers.

The Meenakar often works with a team of

craftsmen. As Meenakari is generally done on the reverse side of Kundan

jewellery, the Meenakar has to work with the goldsmith, the engraver or

ghaaria, the designer or chitteria and jadiya who apply the gems on the kundan

or gold.

The finished produced is a marvel of

the expertise of these different craftsmen and their techniques.

Occurrence

Jaipur is the main center of Meenakari.

Traditional Mughal colours like red, green and white, dominate the art of enamelling

from Jaipur. The rich, ruby red colour used here is highly sought after.

Nathdwara, Bikaner and Udaipur are also

famous for their silver Meenakari. Pratapgarh is known for glass enamelling.

Delhi and Banaras are also important centres

for Meenakari.

Some experts link the historicity of Enamelling in Iran to the Arsacides and Sassanid periods. However, the use of this art in the Islamic period is not clear before the reign of the seventh ruler of Mongol empire’s Ilkhanid division in Iran, Ghazan Khan (694-703 A.D.) who introduced Mongol Persia to Islam.

Ghazan khan acquired the science of

chemistry in a short period and preferred to use his knowledge and endeavours

for the art of enameling.

Approach

Fine silver is used in almost all enamelling

because the enamel (glass) melts and sticks best to a pure metal. In simple

words, enamelling is the process of making metal models (fine silver usually)

and then melting various colours and types of glass on to the object.

Model to create an objet d’art

In a more scientific approach, enamel

(or vitreous enamel or porcelain enamel in US English) is defined as the colourful

result of fusing powdered glass to a substrate by firing, usually between 750

and 850 degrees Celsius.

The powder melts flows and hardens to a

smooth, durable vitreous coating on metal, glass or ceramic. According to some

sources, the word enamel comes from the High German word Smelzan (to smelt) via

the old French Esmail. Used as a noun, an enamel work is a usually small decorative

object, coated with enamel coating.  Meenakari art.

Meenakari art.

A champlevž or a cloisonnž

The paintings or patterns used for

enamel works in Iran are traditional designs depending on the taste and preferences

of the artist. In the Iranian version of Enamelling, copper and silver are the

most dominant metals used. There are also special tools used in this ancient

artistic endeavour such as furnace, pliers, press machine, brush and so on.

Enamel is usually used to embellish

vase, jewellery and candleholder in addition to doors and chandeliers of holy

shrines. Isfahan is the most important Iranian enamelling hub. Enamel works can

be washed with lukewarm water, soap and even ordinary detergents.

Gold has been used traditionally for Meenakari

jewellery as it holds the enamel better, lasts longer and its lustre brings out

the colours of the enamels. Silver, a later introduction, is used for artefacts

like boxes, bowls, spoons, and art pieces.

While copper which is used for

handicraft products were introduced only after the gold control act, which

compelled the Minakars to look for a material other than gold, was enforced

around the world.

Application

Enamel working and decorating metals

with colourful and baked coats is one of the distinguished courses of art in Isfahan.

Mina, is defined as some sort of glass like

coloured coat which can be stabilized by heat on different metals particularly

copper. Although this course is of abundant use industrially for producing

metal and hygienic dishes, it has been paid high attention by painters,

goldsmiths and metal engravers since centuries ago.

In the world, it is categorized into three kinds as below:

1. Painting enamel.

2. Charkhaneh or chess like enamel.

3. Cavity enamel.

What of more availability in Isfahan is the

painting enamel of which a few have remained in the museums of Iran and abroad

indicting that Iranian artists have been interested in this art and used it in

their metal works since the Achaemenian and the Sassanid dynasties.

The enamels being so delicate, we do

not have many of them left from the ancient times. Some documents indicate that

throughout the Islamic civilization of and during the Seljuk, Safavid and Zand

dynasties there have been outstanding enamelled dishes and materials. Most of the enamelled dishes related to the past belong to the Qajar dynasty between the years 1810–1890 A.D. There have also remained some earrings, bangles, boxes, water pipe heads, vases, and golden dishes with beautiful paintings in blue and green colours from that time, afterwards, fifty years of stagnation caused by the World War I and the social revolution followed.

The enamel red colour was prepared in this art from the quantity and quality points of view through the attempts bestowed by Ostad Shokrollah Sani'e Zadeh, the outstanding painter of Isfahan in 1935.

Conclusion

The technique of this art entails perseverance

and deliberation. In Minakari, an ornament is crafted in silver and then the

artist draws the desired design. It is then outlined by the engraver to make

the enamel adhere firmly to the metal. Enameller then brushes the ornament

on the engraved design with special colours called mina in red, green, black,

yellow, blue etc. A single piece of mina passes through many bands before it

reaches completion.

The intricate geometric design pattern

of Minakari symbolizes various elements of a belief structure that has been

evolved since the dominance of Mithraism era in the Iranian plateau.

Here the center medallion symbolizes Mithra,

the Sun. After a few years of stagnation, this art has started to continue its

briskness since 1992.

Author is a fine artist based in Mumbai.

The

purpose of this compilation is to document and promote. We have given credits

and reference links in this compilation. In case some are missed, it is not

with malafide intent.

To read all articles by author